Products

Mixing Emulsifying Series

- > Lab high shear mixer

- > TRH High Shear Dispersing Emulsifier(Intermittent)

- > Jet High Shear Dispersing Emulsifier

- > Pipeline High Shear Dispersing Emulsifier

- > TRL-A Liquid and Powder Mixer

- > TRL-H Shear pump

- > TRS Powder Liquid High Shear Dispersing Emulsifier

- > TRL-B Efficient Online Mixer System

- > TRL-C Suction-Powder Mixing Dispersing Emulsifier

- > Bottom High Shear Dispersing Emulsifier

- > Colloid mill

Sinusoid pump

How It Works

How It Works

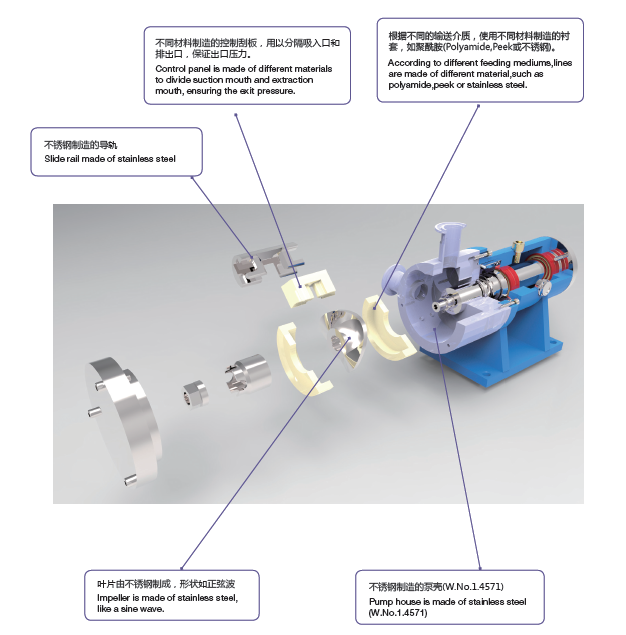

Any exquisite product or good functional product has a simple configuration---including few components….sinusoid pump is not an exception. The sinusoid wave shape of impeller means a cavity can be formed at every rotation (4 cavities can be formed every passing the lining space). This operation can "push" or "release" flowing products. The pump cavity is divided into suction chamber and extraction chamber by control panel to ensure pressure tolerances at exit and entrance. Meanwhile, control panel plays another important role to lubricate the pump bearing by product in compulsion.

Sinusoid pump----excellent efficiency, high viscosity Best selection of super low shear feeding Super low shear feeding Although with a great deal of solid particle and fragile product A safe and no damage feeding can be provided High viscosity performance reaches the limit of flowing capability Can reach 4,000,000cps No pulse, stable feeding Flow cubage adjustment precisely, without interference and shock.Filling machine can supply a stable product dose evenly sinusoid pump: Special two sinusoid-curve-like vane is taken, instead of rotor, epicyclic gear or piston, and it runs with a movable panel and a fixed line, forming a special volume pump and realizing liquid super low shear, without pulse feeding, although in condition of 10bar back pressure (water feeding), there won't be any movement on pressure gauge.

Sinusoid pump----excellent efficiency, high viscosity Best selection of super low shear feeding Super low shear feeding Although with a great deal of solid particle and fragile product A safe and no damage feeding can be provided High viscosity performance reaches the limit of flowing capability Can reach 4,000,000cps No pulse, stable feeding Flow cubage adjustment precisely, without interference and shock.Filling machine can supply a stable product dose evenly sinusoid pump: Special two sinusoid-curve-like vane is taken, instead of rotor, epicyclic gear or piston, and it runs with a movable panel and a fixed line, forming a special volume pump and realizing liquid super low shear, without pulse feeding, although in condition of 10bar back pressure (water feeding), there won't be any movement on pressure gauge.

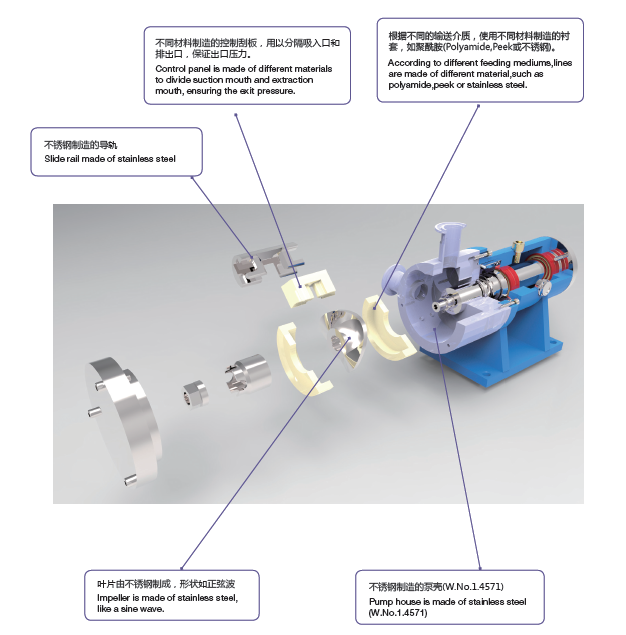

Structural features

Structural features

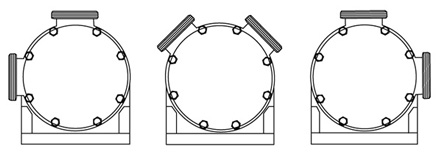

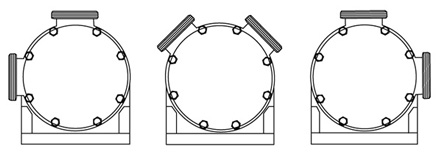

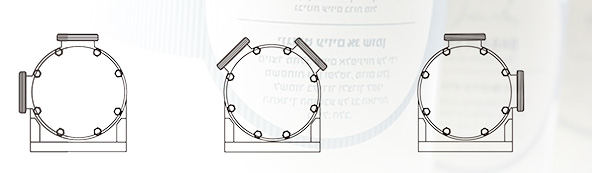

Many interface forms: hoop, thread and flange. Diagram in the under shows the connection directions of entrance and exit which can be selected.

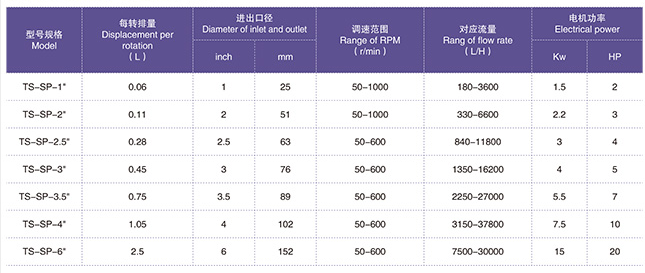

Specifications

Specifications

Application Features

Application Features

Many interface forms: hoop, thread and flange. Diagram in the under shows the connection directions of entrance and exit which can be selected.

Many Configurations Can Meet The Demands Of Different Product Feedings

Your Message

Contact our support team

Products

Products